The EfW process is a form of ‘energy recovery’, a process whereby the exchange or extraction of energy from a source is undertaken with minimal additional energy input.

It works on the principle that energy extracted from processing the waste is greater than the energy input to complete combustions.

The fuel used in an EfW plant is residual waste, which is the waste left once possible recycling has been done. This generally means the environmental or economic costs of further separating and cleaning the waste exceed any potential benefit of doing so. This waste would traditionally go to landfill but in EfW is used to generate electricity and heat.

EfW plants suffer from an outdated perception they emit harmful pollutants, meaning developments can often be contentious. Whilst emission control on the earlier incineration/EfW plants could have been better, these have now ceased operation with strict regulations governing their emissions, namely Industrial Emissions Directive (2010/75/EU). In fact, the Environment Agency has pointed out that the emissions from London's one-minute-long millennium firework display equalled 120 years’ worth of dioxin emissions from the South East London Combined Heat and Power EfW facility.

There have been several studies undertaken focusing on the effect of EfW emissions and these have demonstrated there is no or negligible health effect on local populations. In fact Public Health England concluded in a 2010 report into the impact on health of emissions from waste incinerators that “any potential damage to the health of those living close by is likely to be very small, if detectable.”

Generating Green Energy

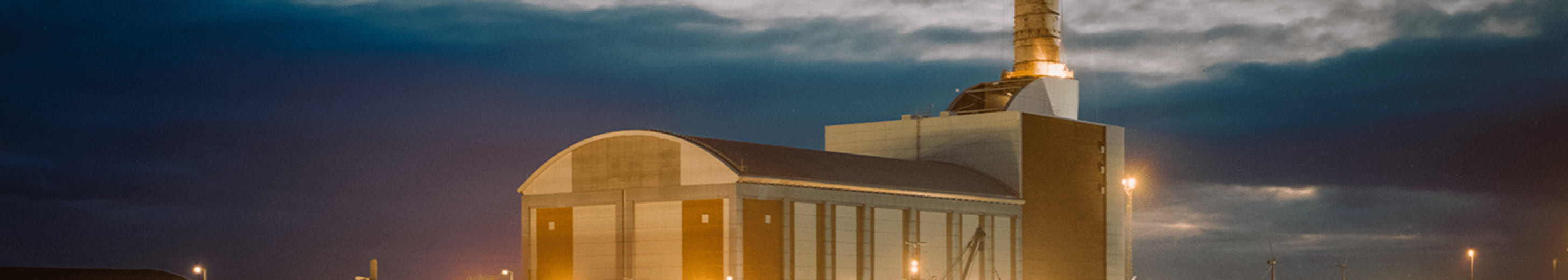

There are 40 EfW plants in the UK, with 15 in construction and 2 in the commissioning phase. Their operation comprises of the combustion of residual waste, to heat water used to drive a turbine and generate electricity. In some cases, known as Combined Heat and Power (CHP), heated ‘Process Water’ is also utilised, often via a ‘District Heating System’, through which heated water is distributed to nearby buildings for space heating. In some cases, the steam can also be supplied at high pressure to nearby sites for used in industrial processes instead of onsite production of steam using gas, oil or coal-fired boilers.

EfW fuel contains a mix of renewable and non-renewable compounds; the organic component is considered renewable, whereas the non-organic components, such as unrecyclable plastics, are not. Overall, the energy released is considered to be ‘green’, that is to say it is a partly renewable source of heat and power. This means that EfW plants can produce energy in a more sustainable way than typical coal or gas-fired power stations yet can still contribute to the electricity network’s baseload generation, as opposed to the intermittent nature of renewable generation such as wind and solar. The energy generating capacity of these plants ranges from 10MW to around 80MW.

Carter Jonas helping the shift to cleaner, greener energy

Perhaps you occupy a building near an EfW plant and would like to explore a ‘private wire’ or heat supply agreement to capitalise on the greener and cheaper heat and/ or power they can offer. We support both developers and off-takers in these scenarios.

Carter Jonas offers a full suite of services to the EfW industry from funding, initial site identification, land assembly and feasibility at the earliest stages, through acquisition, planning and procurement, to negotiated exits through our dedicated agency team. Advice lead by Miles Thomas (Partner – Energy) available on 07500 126291 or at miles.thomas@carterjonas.co.uk. Carter Jonas also provide advice in respect of Minerals & Waste in their dedicate team, contactable through Michael Hayes on 07880 357995 or michael.hayes@carterjonas.co.uk

Any business needing advice on the aspects mentioned above, or would like to find out how they may benefit from a nearby EfW development should contact Daniel Turner (Infrastructure & Energy Team) on 07552 973852 or at daniel.turner@carterjonas.co.uk.

Read this month's energy news >

Read the latest energy market update >